The Challenge of Neutron Radiation Shielding

Because neutron radiation endangers the people, structures, devices, and equipment exposed to it, reliable neutron shielding protection is critical. Specially designed shielding walls are used in nuclear power facilities, nuclear medicine systems, radioisotope projects, or particle accelerator work.

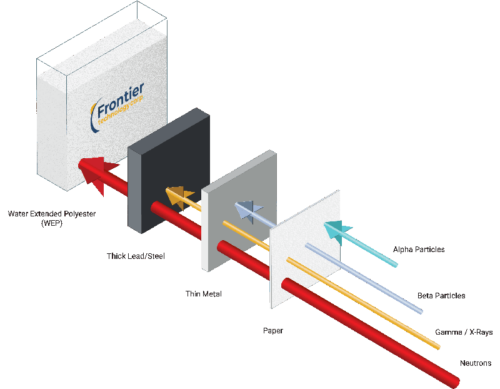

Many materials may be used to shield against ionizing radiation. However, the three most popular neutron shielding materials are WEP resin, paraffin, and concrete. Notably, dense materials, such as lead, are less effective at blocking neutron radiation and are not used for neutron shielding.

WEP Neutron Shielding

Hydrogen and hydrogen-based materials, such as water and water-extended polyester (WEP), are preferable for neutron shielding. This is because compounds with a high concentration of hydrogen atoms act as reliable barriers and provide inexpensive yet reliable shielding.

Frontier’s shielding walls incorporate materials made of low-atomic-number elements because they have a high probability of forming cross-sections that interact with the neutrons.

"*" indicates required fields

Neutron Shielding Walls from Frontier

Frontier’s WEP resin is an ideal material for neutron radiation shielding because:

High Water Content: As a result of the emulsification process, WEP resin’s final hydrogen content is almost as high as that of pure water. Unlike water, WEP resin cures into a hard shield, so it can easily be used in almost any shielding application.

- Cost-Effective: WEP resin’s high water content makes it a very affordable substance by weight compared to alternative materials.

- Harsh Environmental Resistance: WEP is completely inert. It doesn’t break down and resists damage from water exposure, weathering, and harsh chemicals. WEP is also fire-retardant (although best-suited for normal operating temperatures).

- Void-Free Curing: WEP resin sets cleanly and with minimal imperfections and no odor. It cures as a contiguous solid material with no voids, holes, or bubbles.

Custom WEP Neutron Radiation Shielding Solutions

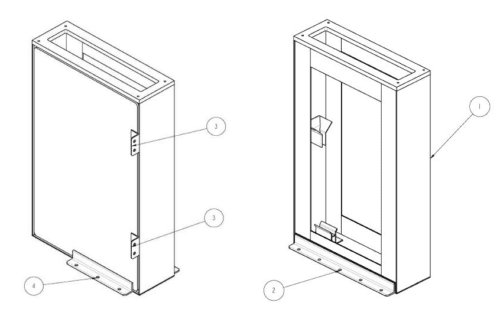

Our shielding walls are custom-manufactured to your requirements, constructed with stainless steel outer materials, and contain WEP inner material. Our neutron radiation shielding options include:

- Custom dimensions available

- Isotope pass-through ports

Frontier can also use WEP to fill shielding walls that our customers have designed and supplied to us.

Frontier's Custom Shield Wall Manufacturing Capabilities & Provisions

| Types: | Walls |

| Shielding | |

| Outer Material: | Stainless Steel |

| Inner Material: | Filled WEP (Water-extended polyester) |

| Thickness: | Custom Dimensions Available |

| Height: | Custom Dimensions Available |

| Width: | Custom Dimensions Available |

| Options: | Isotope Pass-Thru Ports |

| Production Volume: | Prototype |

| Production | |

| Testing Services: | Void Volume |

| Meter Testing | |

| Quality Control: | QA Manual |

| Additional Services: | Documentation |

| Integration | |

| Product Design | |

| Project Management | |

| Reverse Engineering | |

| Technical Support | |

| Project Lead Time: | 8-to-14 Weeks (based on inventory and scheduling) |

| Expedited Services Available |

About Frontier Technology Corporation

Frontier Technology Corporation (FTC) is the world leader in californium-252 neutron source manufacturing and design, and is the foremost expert in logistics and shipping of radioactive material. Founded in 1984 by Treva Janzow and the late Edward Janzow, Frontier Technology is located in Xenia, Ohio. Frontier Technology has over 40 years industry experience in providing the highest-quality neutron sources, PINS sources, nuclear start-up rods, TYPE-A shipping containers, WEP shielding, and antimony-beryllium pellets.

Type-A Neutron Shipping Containers

Frontier designs and fabricates “Type-A” shipping packages of various sizes, shielding, capacities, and configurations for use, rental, or purchase by our customers. All packages are designed and constructed in-house to ensure that the highest quality standards are met.

Type-A Shipping ContainersWEP: The Best Neutron Shielding Material

WEP resin is a newer shielding choice valued for water’s high hydrogen availability. Due to its high content of large, neutron blocking hydrogen molecules, WEP is a highly effective shielding material. It also contains boron, an element that absorbs neutrons and adds additional shielding capability. WEP resin is strong, versatile, durable, and offers better neutron shielding performance than some high-density options.

WEP: The Best Neutron Shielding MaterialNuclear Shielding Applications

Neutron radiation poses significant danger to people, structures, devices, and equipment exposed to it; therefore, effective neutron shielding is critical. In plants, labs, and other buildings where neutron sources and equipment are used, shielding walls are an excellent way to protect against neutron radiation.

Nuclear Shielding Applications

High Water Content: As a result of the emulsification process, WEP resin’s final hydrogen content is almost as high as that of pure water. Unlike water, WEP resin cures into a hard shield, so it can easily be used in almost any shielding application.

High Water Content: As a result of the emulsification process, WEP resin’s final hydrogen content is almost as high as that of pure water. Unlike water, WEP resin cures into a hard shield, so it can easily be used in almost any shielding application.