Nuclear energy is a leading green energy source due to its low carbon footprint, but it must be managed with proper shielding to prevent workers, the general public, and the environment from nuclear radiation exposure. Without appropriate nuclear shielding technology in place, a nuclear plant puts people at risk for certains cancers and other health hazards. These risks make it vital to invest in the best nuclear shielding technology when storing and handling radioactive materials.

What Is Nuclear Reactor Shielding?

Nuclear reactors produce nuclear energy through the nuclear fission of highly radioactive materials. Fission splits up the elemental nucleus and releases high amounts of radioactive energy, which is harnessed and converted into clean electricity. These radiation waves require unique materials to protect the surrounding environment from contamination.

A nuclear reactor shield is fitted around the reactor to absorb any radiation from leaking into its immediate environment. Usually made of lead or special types of plastics, shielding is necessary for both the transportation and storage of radioactive neutron sources.

Transport and Storage: Nuclear Shielding Logistics

Nuclear shields are essential in nuclear storage plants and transport equipment. Before choosing a nuclear reactor shield, you should consider the time under exposure, distance from the exposure, and the type of material necessary.

Types of Nuclear Shielding

Type A shipping containers can transport nuclear materials without exposing personnel or the environment to neutron source radiation. They can be customized to handle radioactive materials and have passed rigorous testing such as:

- Water spray for at least one hour to simulate rainfall of 2 inches per hour

- Freefall drop test on a hard surface

- Compression of at least five times the maximum weight of the package

- Penetration tests using a 13-lb metal bar

Common Encasement Materials

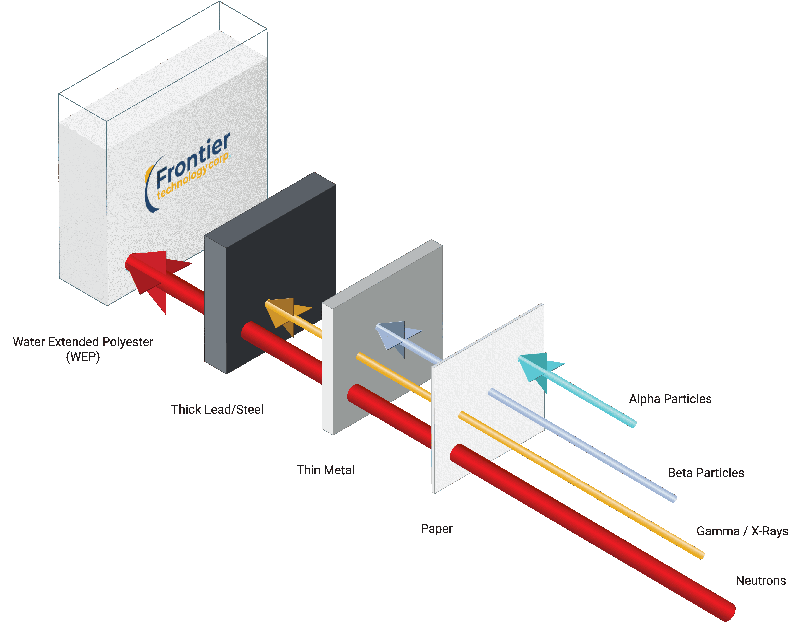

There are different types of materials that make effective nuclear shields. They form a barrier between the radiation source and personnel, reducing or eliminating their radioactive dose.

Traditional Lead

Lead has a unique chemical and atomic structure that effectively blocks gamma rays and X-rays. The atomic orbitals inside lead atoms are closely bound, preventing radiation waves from penetrating. It is an effective and affordable option to protect people from radiation exposure.

Lead Composite

In lead composite shielding, lead is mixed with other compounds and elements with low atomic numbers to enhance its shielding abilities. Frontier Technology’s composite shielding is a proprietary blend of lead and other metals that is lighter but just as effective at blocking radiation.

Lead-Free

One drawback of using lead is that it is non-biodegradable and carcinogenic. It is also less effective at blocking neutron radiation. Water extended polyester (WEP) from Frontier Technology is an effective alternative, as it is a water-rich resin with fire resistance capabilities and high mechanical strength. Its high concentration of hydrogen makes it an effective shield against neutron radiation during shipping and storage.

Industrial Uses of Nuclear Reactor Shielding

Companies in the nuclear energy industry use nuclear reactor shielding technology in land-based plants, submarines, and transport operations. Shielding is vital to limiting workers’ exposure to nuclear radiation when near the source.

Shielding Solutions for Nuclear Reactor Plants

Frontier Technology offers tried-and-tested neutron source manufacturing and shielding solutions. Our nuclear reactor shielding Type A containers meet industry standards for transporting radioactive materials, including Californium-252. Contact us to learn more about our nuclear shielding storage and transportation solutions.