Boreholes are used to obtain direct information about the soil below the ground surface at a specified location. Traditionally, drill cores would be extracted and examined in a laboratory to determine the lithology at the drill site, as well as other physical and petrographic properties. For myriad technical or economic reasons, however, it is not always practical to examine drill cores from every borehole.

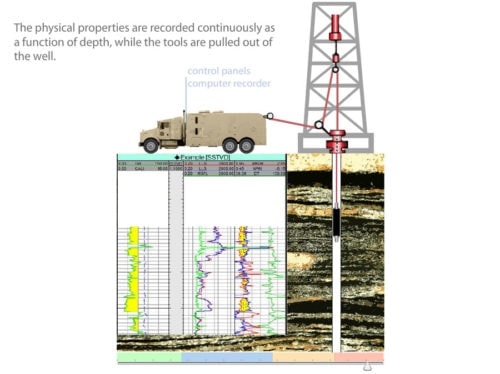

Oil well logging, also known as borehole logging, is a process where specialized instrumentation is inserted into a borehole to determine the properties of the geological formations surrounding the bore. The in-situ nature of borehole logging is crucial since it allows continuous depth measurements of the formation properties to be taken while the borehole material is still under existing pressures and temperatures.

How Does Oil Well Logging Work?

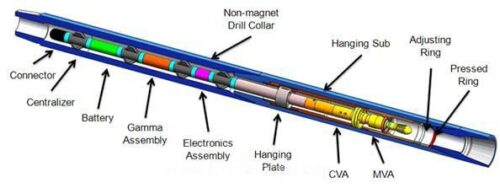

During oil well logging, the logging tool is lowered into the borehole via a cable. Relevant data is transmitted electrically through the cable to the surface, where they are digitally and continuously recorded as a function of the depth of the formation.

The data obtained from oil well logging reveals lithological classification as well as various physical, chemical, and structural properties of the formation around the borehole. Some of the detailed information that can be obtained from borehole logs includes:

- Rock composition: information on strata types (limestone, shale, sandstone, etc.)

- Rock characteristics: porosity, permeability, presence of liquids

- Rock integrity: presence of structural weaknesses, risk of cave-ins

- Borehole dimensional properties: size, shape, borehole trajectory

- Liquid presence: properties of the fluids (if any) present in the borehole (e.g., salinity, pressure, saturation, etc.)

Of the methods for borehole logging and formation evaluation, measurement via neutron porosity is one of the most efficient. This technique involves using a neutron source to measure the porosity of a formation by determining its hydrogen index.

During this method, the source emits high-energy neutrons which bombard the walls of the formation. The neutrons then lose energy due to elastic scattering before being absorbed by the nuclei of the formation atoms. Upon absorption, gamma rays are emitted and detected by the detector in the borehole which measures the neutron population, epithermal neutron population, thermal neutron population, or amount of gamma radiation emitted after absorption.

Since the speed of the neutrons is highly sensitive to the presence of hydrogen, this method is especially effective at detecting the quantity of hydrogen atoms in a formation, which is indicative of the formation’s porosity.

Oil Well & Borehole Logging

Californium-252 in the Oil and Gas Industry

The oil and gas industry uses neutron emission sources—such as Californium-252 (Cf-252)—to gain information on the quality and characteristics of the borehole and ultimately determine the feasibility of extracting hydrocarbons from the drill site.

Petroleum engineers also use well logs to help identify the sedimentology of oil wells. Since hydrocarbons tend to accumulate in sedimentary rocks which are permeable and porous, oil well logging helps provide valuable data on which formations are most likely to contain gas reserves.